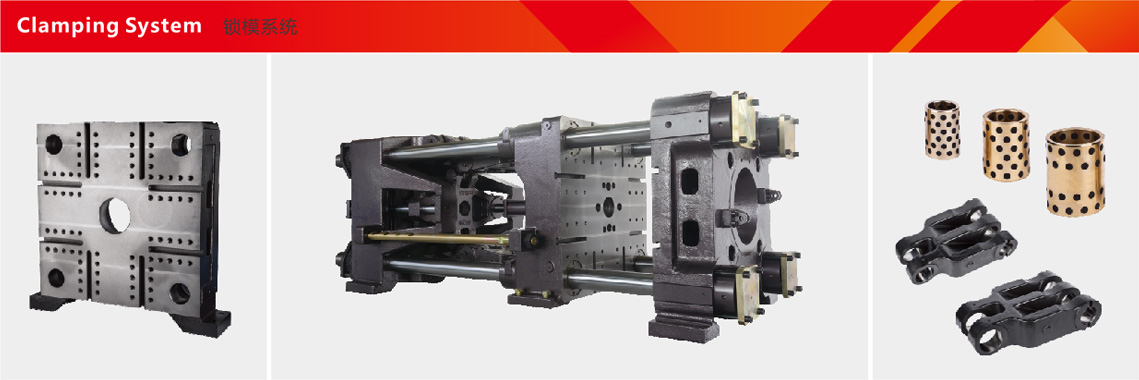

The more rigid clamping mechanism meets efficient and fast production requirements.

Superior open mold features, running faster and more stable.

Five pieces of elbow bar mechanism by advanced computer optimization, template, bracket with Siamese structure, good rigidity, high precision assembly.

Professional template optimization design, template by advanced finite element analysis software to optimize the design, high rigidity, high strength, to meet the needs of fast, impact conditions.

High-strength mechanical structure design, to ensure lasting accuracy

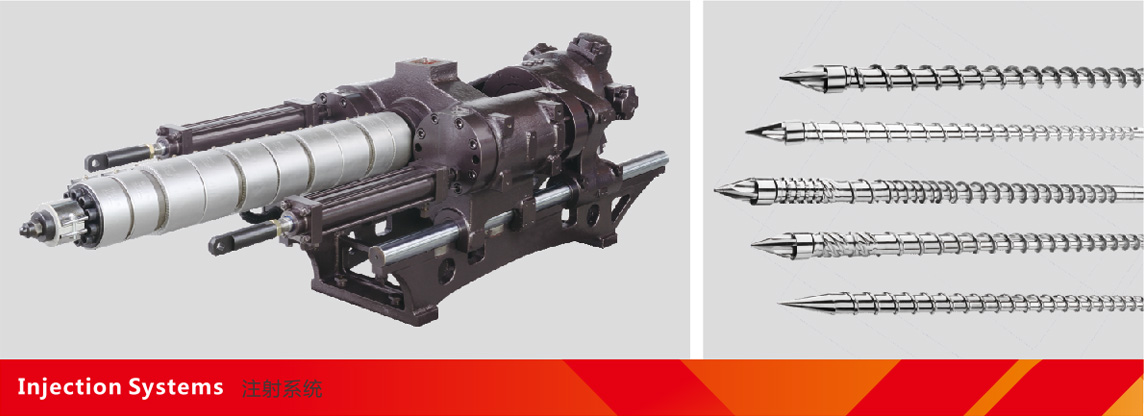

Double cylinder balanced injection structure to make reliable, strong pressure

Precision electronic scale control injection, melt stroke

Professional plasticizing unit for a variety of raw materials to produce professional plasticizing unit, professional heating power device, significantly improve the plasticizing performance.

For different types of plastic and processed product features, can provide a dedicated screw to meet customer needs; such as: UPVC, PMMA, PA, PC, CP, PPS, PET and so on.

The use of injection molding machine dedicated computer, large-screen high-definition LCD display, man-machine dialogue to facilitate the operation, CPU computing speed, reliability, and scalability.

High-quality electrical components, to strengthen the hardware circuit, anti-interference ability, more reliable operation, more stable.

High precision computer controller and servo drive combined, high economic efficiency. The overall speed of more than 20% increase, more efficient machine, so that more mold cavity forming more stable.

The hydraulic unit consists of the world famous brand oil pump and hydraulic valve, the pressure bearing performance is more excellent, more effective protection of the machine's accuracy, reliability, stability and durability, and has low noise and environmental characteristics.

High performance servo motor power control system

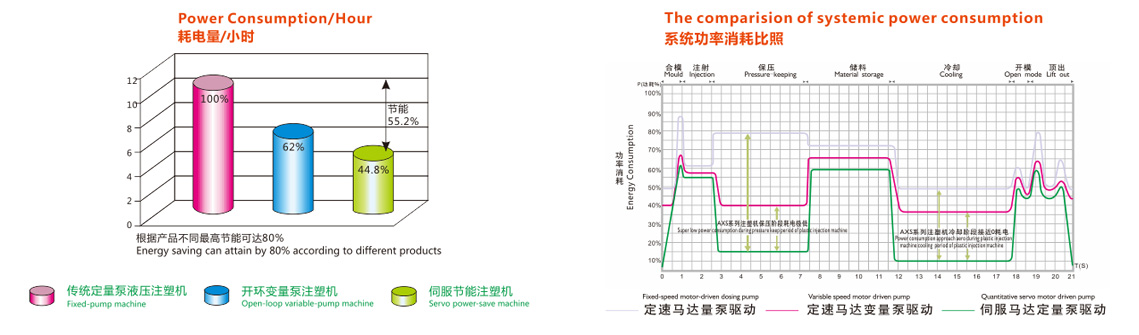

1、Super energy

The output power changes with the load changes, there is no waste of excess energy, holding the stage of low-speed operation of the servo motor, energy consumption is very low, the cooling stage of the motor does not work, power consumption is zero. Compared with ordinary injection molding machine, energy saving of 30% -80%.

2、Precision and stability

Equipped with high precision, highly sensitive rotary encoders, pressure sensors, respectively, on the flow and pressure monitoring and feedback. According to the feedback information, high-performance synchronous servo motor by changing the speed and torque on the flow and pressure to adjust accordingly, the formation of high-precision closed-loop control, thus ensuring product quality and stability.

3、High efficiency, high efficiency

Servo energy-saving injection molding machine drive system responsive and quickly, only 0.05 seconds to achieve the maximum input value. The response speed is much faster than the ordinary injection molding machine drive system, which significantly shorten the molding cycle, the production efficiency has been greatly improved.

Power consumption is less than 50% of the traditional hydraulic injection molding machine, with the same electric injection molding machine, especially in the pressure, cooling stage, energy saving effect is particularly prominent.

Servo energy-saving injection molding machine is equipped with a high-performance servo motor power control system, the servo motor output power changes with the load changes, there is no excess energy loss, the load stage motor speed to reduce the speed, low energy consumption, cooling stage motor does not work , Energy consumption is zero, to improve the injection accuracy at the same time, a substantial energy saving, water saving, reduce noise. The real realization of the hydraulic injection molding machine a new revolution.